Applicable Industries: Manufacturing Plant

Showroom Location: Viet Nam, South Korea

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: Hot Product 2571

Warranty of core components: 1 Year

Core Components: Motor

Condition: New

Automatic Grade: Automatic

Type: Inking machine

Voltage: 220V

Power: 80W

Dimension(L*W*H): 470*550*440mm

Weight: 42 KG

Warranty: Check

After-sales Service Provided: Engineers available to service machinery overseas

Usage: leather Edge Grinding Machine

Product name: Horizontal Leather Belt Oil Edging Machine

Features: Single sided

Function: For Belt Bag Edge Making

Keywords 1: Leather edge Coloring painting machine

Keywords 2: Kamege belt edge oil inking machine

Useful: bag leather dyeing machine

Title: Single Sided Leather Edge Dyeing Coloring Oil Inking Machine

Application: Leather Goods

Packaging Details: XD-115 Kamege belt edge machine is packed with pallet,wooden case,plastic film with pearl wool.

Port: HangZhou

Machine Name:Single Side Belt Coloring Inking MachineModel:XD-137Dimension:490*450*415mmNet weight:41kgCharacteristics:The machine is suitable for the belt factory,handbag factory,all kinds of men and women belt head,leather accessories,irregularleather edge oil,with double speed regulationg device,oil and speed are free to allocate.Cooperate with device can realize semi-automatic operation.Instructions:1.Check whether the machine voltage (220V) are in conformity with the power supply voltage.2.Open the power,adjust the flywheel run to adjust to fit the machine speed.3.Pour the side oil into the three-quarter position of the oil side box. Please do not overfill.4.According to the need to twist adjusting nut oil to fuel control to the quantity of oil required for the product.5.Clean the machine when open the power supply with film first scraped off on the side of the tanker oil,and then turn off themachine power supply,remove the oil box fixed nut,remove the oil box rinse immediately with water.

| Model | XD-137 |

| Brand | Kamege |

| Machine dimension | 490*450*415mm |

| Voltage | Single phase 220V |

| Net weight | 41kg |

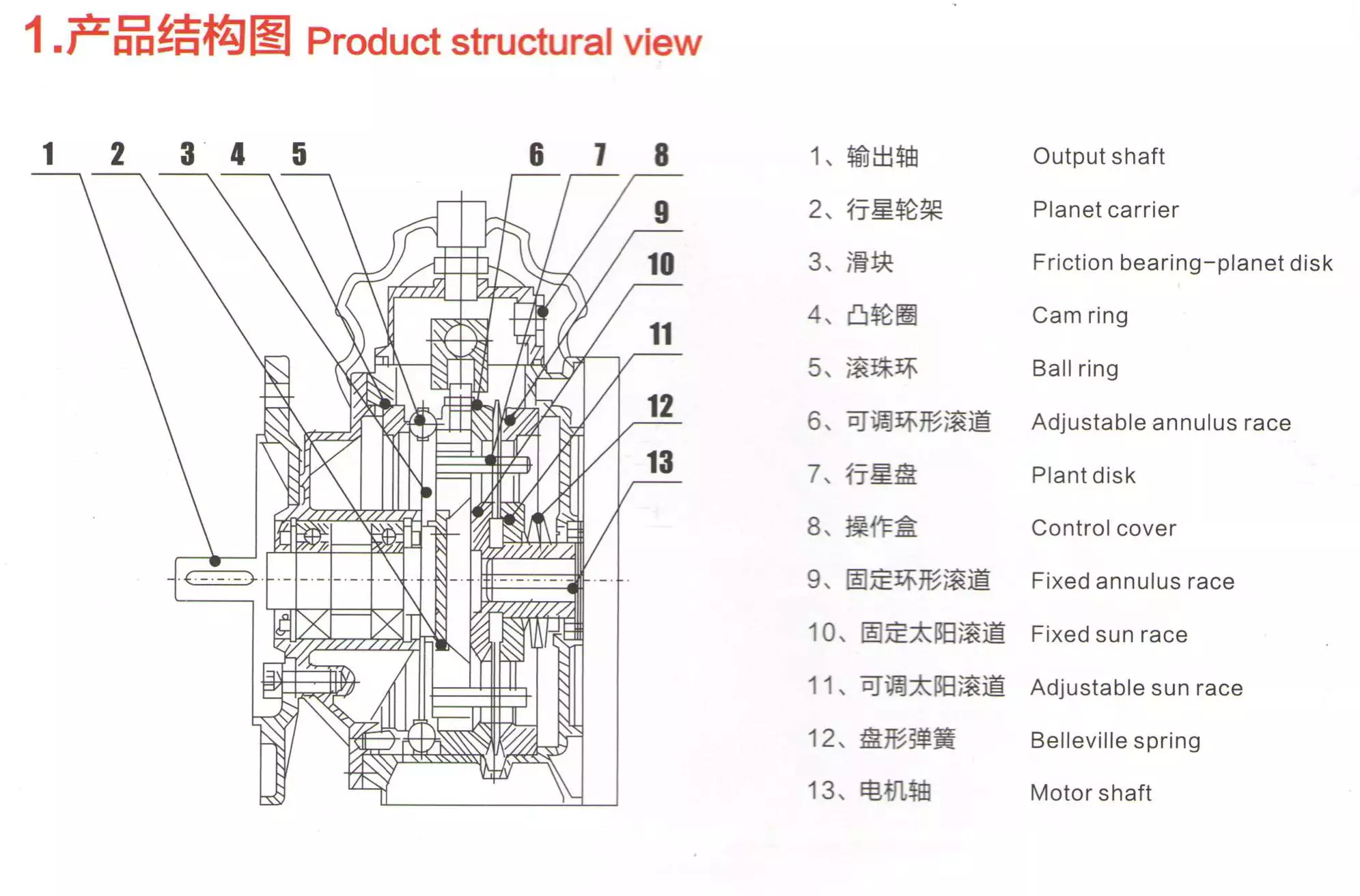

What Is a Speed Variator?

Speed Variator is a device that helps you to control the speed of your machine. There are different types of Speed Variators available in the market. You can choose a mechanical one if you are looking for a low-maintenance one. These are available in low price and come with reliable features.

Input shaft 30

A Speed Variator works by rotating the output shaft and the input shaft in opposite directions. In this case, the input shaft is mounted on frame 13 and the output shaft is fixed to frame 30. The sun wheel is fixed to the output shaft. The speed of a Speed Variator is proportional to its speed.

A Speed Variator is a special type of speed converter that is used to change the gear ratios. It works in a similar manner as a planetary gearbox. The input shaft and output shaft are connected to each other through toothed gearing. The gearing also links the variator to the controlling element of differential gearing.

The input shaft extends from the prime mover (or engine) 125 to the second speed-variator assembly. It then extends into the housing 2, where all the motion-transmitting parts are housed. Keys three and six fix input shaft 1 to the gear wheel 4, while shaft 7 forms the driving shaft of the first speed-variator assembly A. Similarly, shaft 3 is journalled in a lateral sliding carrier 9 and is connected to the second speed-variator assembly B.

A rotary shaft encoder 60 is mounted on the shaft portion between the planetary gear unit 50 and the generator 110. The encoder sends data about the number of revolutions per minute to a speed-control module 70. This module controls the speed-control module 70, which in turn controls a positioning motor 80. Similarly, a planetary wheel 19 can produce a negative torque.

Multiplier group 50

The multiplier group 50 comprises two arms that are rotatably mounted on a slide 20 by means of an interposition bearing 21. The first arm corresponds to the first hinge axis 40 of the drive shaft 1 while the second arm is coupled to the first end of pin 4 of the sprocket 5. Both arms are positioned at right angles to one anaother.

The first group is called the multiplier group 50 and the second group is known as the multiplier group 60. The two groups work together to multiply the output. When they are both set to the same value, the final multiplication is doubled. The ratio is 1:1 between the driven shaft 9 and the drive shaft 1. The largest ratio is provided by the carriage 10 at its maximum translation distance.

The variator can be used in bicycles, automobiles, agricultural equipment, ships, and mechanical equipment. It can increase the working range of any motor or wind turbine. It can also be used in conjunction with steam or water generators. It is shown schematically in Figs 21A-22A-23A.

The mechanical continuous gear variator 100 is based on a kinematics chain. The drive shaft 1 is rotatably mounted on the frame 13, while the driven shaft 9 is coupled to the movable translation means.

Transfer element 7

A Speed Variator is a mechanical device that can vary the speed of a motor. The mechanism of this device consists of a geared wheel that is keyed to one of two shafts. The geared wheel transmits motion to a transfer element and sprockets. The geared wheel also transmits motion to a thrust element, which is interposed between the sprocket and transfer element. The thrust element includes a slide, two arms 22, and an elastic element 24.

The input shaft 1 starts the rotation of the driving gear wheel 2. The carriage 10 moves through sprockets 5 that are permanently geared to the driving gear 2. The freewheel mechanisms 3 lock the gear 2 relative to the carriage 10, which then transmits the motion to the transfer element. The sprocket 5′ is connected to a pin that has a smaller radius than the driven shaft 12, which then transmits the motion to the transfer elements 7, 14.

The Transfer element 7 is arranged in a chain-like fashion and acts as the final gear of the transmission. The drive shaft is rotatably mounted on the frame 13. The movable translation means are coupled to the driven shaft by an adjustment means.

Rotational axis of the variator 100

The rotational axis of the speed variator is the axis that is symmetric about the x-axis. In this case, the first group 50 of the variator 100 multiplies the second group 60. This gives the final multiplication the same ratio for both groups. This ratio is 1:1 when the drive shaft 1 aligns with the driven shaft 9. When the carriage 10 is translated the maximum distance, the ratio is the highest.

Variators work by transferring rotary motion between input shafts. Variators are designed to reduce energy consumed for motion transfer, and this invention provides a speed variator with these features. In addition, the new unit allows for rapid adjustments of the output rotation speed. The mechanism is easy to adjust and consists of simple, low-cost elements.

The mechanical continuous gear variator 100 comprises a drive shaft 1 and a driven shaft 9. The driving shaft 1 is coupled to the driven shaft 9, and the driving shaft is mounted on the rails or carriage. The output shaft 12 is mounted on a rotatably mounted frame 13.

Operation of the variator 100

The speed variator 100 is a mechanical device that varies the speed of a motor. This device is connected to a shaft that is connected to the output shaft of the motor. It has a second group of gears that are coupled to a shaft that is connected to the first gear group 50. This arrangement causes the speed of the second device to vary continuously.

A mechanical continuous gear variator 100 has a first multiplier group 50, a gear 1 mounted rotatably on a shaft, a second gear that is mounted rotatably on the shaft, an intermediate shaft, and an output shaft. The shafts are coupled together with a frame.

The speed variator is operated by a controller that is supplied with control codes. A variable-load controller (Code F) enables the operator to control the speed of an induction motor using a proportional adjustment. A potentiometer provides feedback to the electronic card. A regulator with this type of feedback allows continuous control of the unit’s speed.

A good variator can improve your bike’s performance, but it’s important to choose the right one for your bike. It’s not a complicated process if you follow a few rules. The Daytona Drag is a good choice if you’re looking for a high-performance variator. It’s wider and has longer roller ramps that are closer to the crank than the Posh.

Dimensions of the variator 100

The dimensions of a speed variator 100 will depend on the diameter of the drive face, the ramp length, and the distance between the movable drive face and the floor of the ramp. The ratio is determined by these three factors, along with how well the movable and fixed drive faces fit together.

editor by czh